How are golf shoes made? As someone who often has to review the technology in our sport’s required footwear, it’s a question I ask myself quite often. So I headed to Adidas headquarters in Basingstoke to find out about the process from design to being on your feet…

Typically Adidas golf shoes take 18 months to design from start to finish. However Adidas also have a futures team that are working five or more years ahead on new technologies that will be included in upcoming editions of their golf shoes.

The team can have an initial concept which could be new materials or new shaped spikes on the sole but these all have to be tested to prove they are viable.

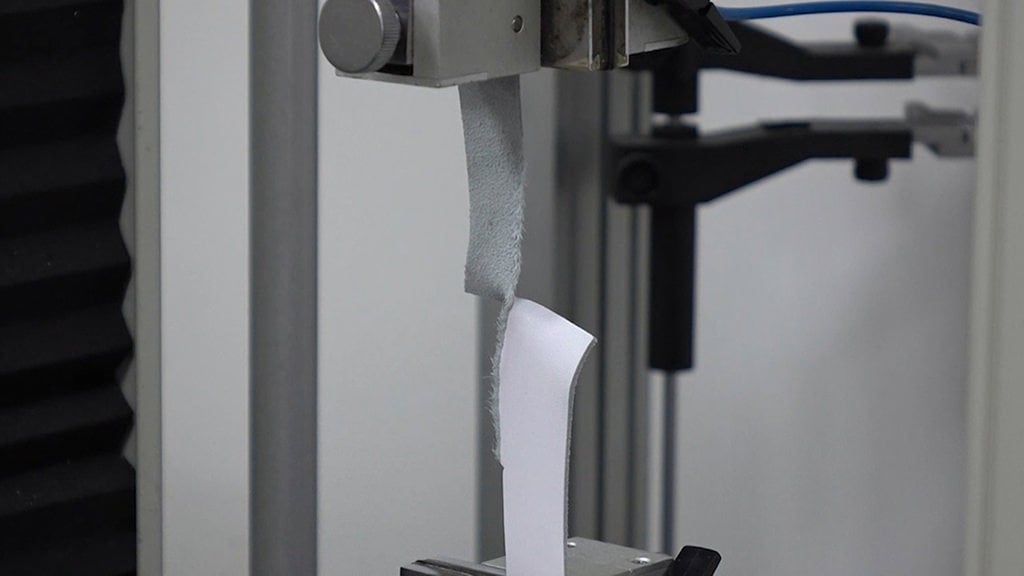

All new materials go through rigorous testing to make sure they meet Adidas requirements before they can be included in any designs. This was the same when collaborating with Parley on the new Parley Tour 360 XT shoes.

“Having Parley involved was new for us because we’ve never worked with their materials,” Adidas Golf’s head of global footwear Masun Denison tells me. “So there are certain guidelines we have to hit to be apart of the Parley story. Every part of the shoe gets dissected we have to use recycled plastic for the outsole, the upper has to have the Parley stitching material in it, there’s certain colours that we have to use.”

“In some ways its harder to get it to perform at the right level, to find the recipe within that sustainable material. Sometimes you’re paying more for it so the costs go up a little. But if we can be part of cleaning up the world but giving you a really amazing product at the same time, that is a win win.”

Advertisement

Another example would be the new X-shaped sole design in the Tour 360 XT. The design team started looking at shapes and how they provide strength and structure. But from there they had to do a lot of drag testing with their cleat manufacturer dragging the shape on a grass surface and looking at the resistance force to that drag test.